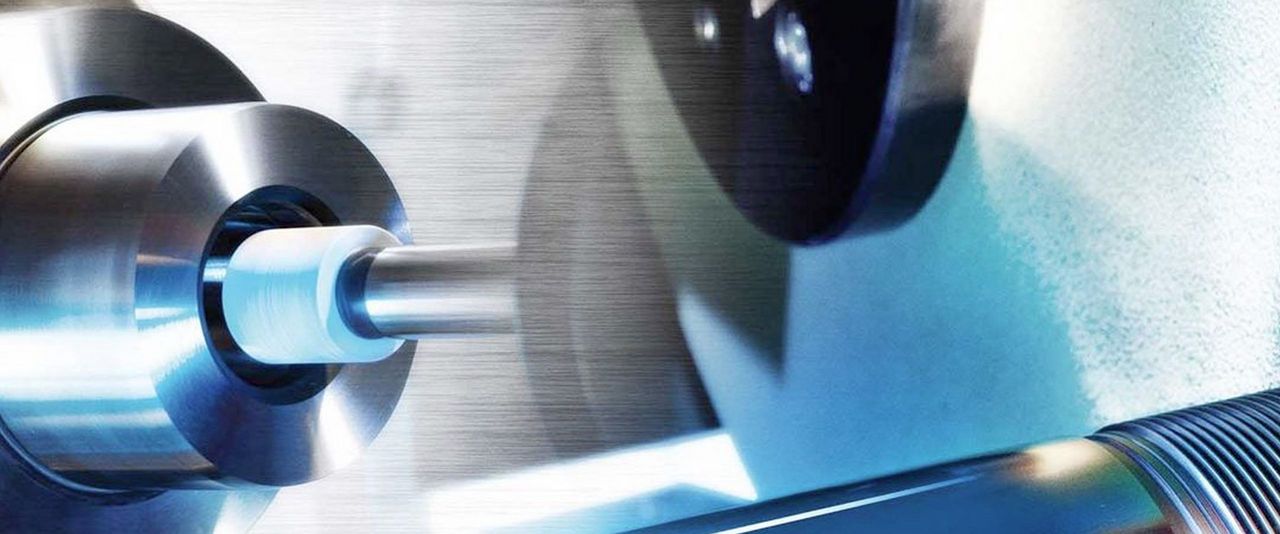

Keep a clear perspective during cylindrical grinding

To successfully grind a workpiece on a cylindrical grinding machine, each part of the system must be correct and each step of the process must be perfect. Even a single flaw can cause the entire process to fail. You need the right settings, the right grinding wheel and the correct coolant and working environment to produce a precise part with an excellent surface finish. Errors lead to rejects, wasted money and reduced efficiency. That is why it is crucial to inspect the finished parts carefully to identify and correct any problems associated with the grinding process.

Five factors that can lead to complications

Most complications can be traced back to one or more of the five typical influencing factors. The process parameters (feeds and speeds) are top of the list, along with the choice of grinding wheels and dressing tools, the amount and condition of the coolant and the clamping method used.

1. Upstream processing steps

The upstream machining operations preceding the grinding process increase the pressure to achieve flawless grinding results. We will not leave you alone in this process. You are always welcome to take advantage of UNITED GRINDING's training opportunities: from help in purchasing new machines to familiarizing yourself with new production processes and training new employees. We can, of course, also provide on-site assistance to help you solve tricky process problems or develop optimization approaches for your individual production tasks.

However, before you have to call for help, you can already diagnose many possible causes of errors yourself through observation and a little detective work. A well-ground part will include a surface gloss with a silky texture that is free from irregularities, blemishes or scratches. Many grinding errors will become obvious when you inspect a finished workpiece and identify distinctive patterns. You can often recognize these errors with the naked eye – in many cases as characteristic surface patterns.

2. Poorly dressed grinding wheels

Poorly dressed grinding wheels are often responsible for visible grinding errors. If a wheel is dressed too quickly or from different directions, its surface becomes uneven and leaves a repetitive pattern of spiral markings on the workpiece surfaces. A dressing tool that shifts, heats, or wears causes a form in the grinding wheel that is not parallel to the table axis. In this case, you will see a pattern of feed tracks on the surface of the workpiece.

3. Coolant problems

Problems with the coolant can also transfer to a workpiece surface and appear there as defects. Short scratches resembling commas are caused by coolant that is contaminated with grains from dressing. Yellow or brown discolorations indicate burn marks from an overheated grinding process or insufficient cooling, both dangerous conditions that can lead to thermal cracks in the workpiece and changes in the material structure.

4. External influences

External influences from other machines and equipment nearby, can cause vibrations that may have an effect on the smooth operation of a grinding machine. These interfering factors are visible as marks parallel to the work axis over all or part of the workpiece surface – the so-called chatter marks.

5. Unbalanced grinding wheels

An unbalanced grinding wheel can cause chatter marks on the entire surface of the workpiece parallel to its axis. The same marks can also be an indication of external vibrations or an incorrect ratio between grinding wheel and workpiece speed. To increase the stability of the system, use a steady rest to keep very long parts stable, rigid and centered during grinding.

There is no real secret behind resolving visually recognizable grinding errors. To refine the process so that the workpiece has the correct tolerances at the end, the machine must be set up and maintained correctly, the grinding wheels must be properly dressed and the cooling process must function flawlessly.

Whether you are faced with a production problem or simply want to improve your grinding process, UNITED GRINDING is here to help you achieve the best possible results with your cylindrical grinding machines.