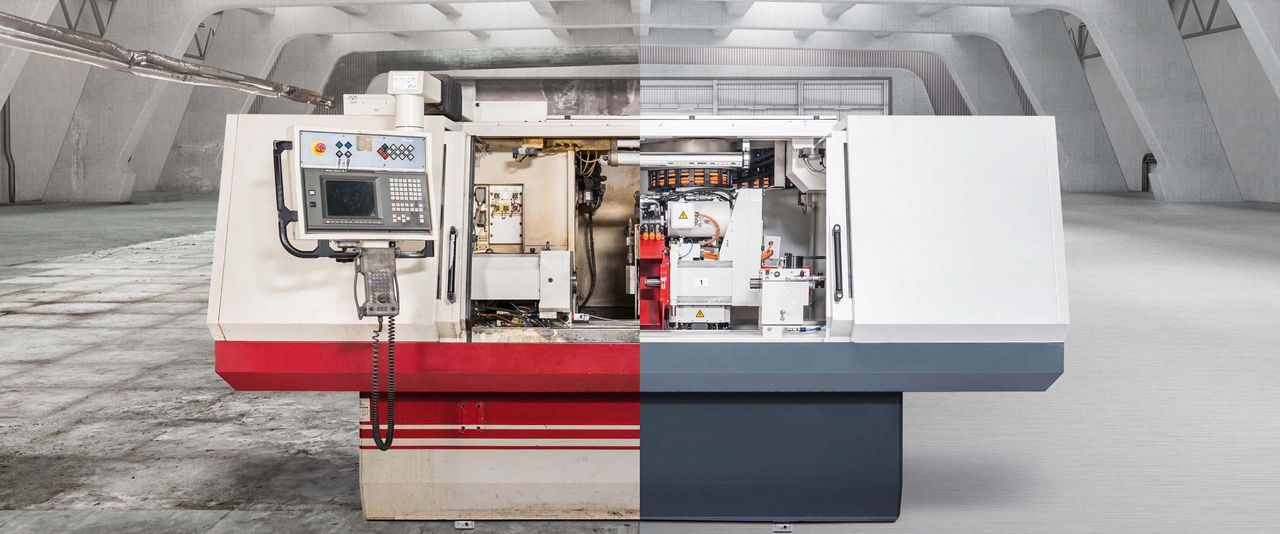

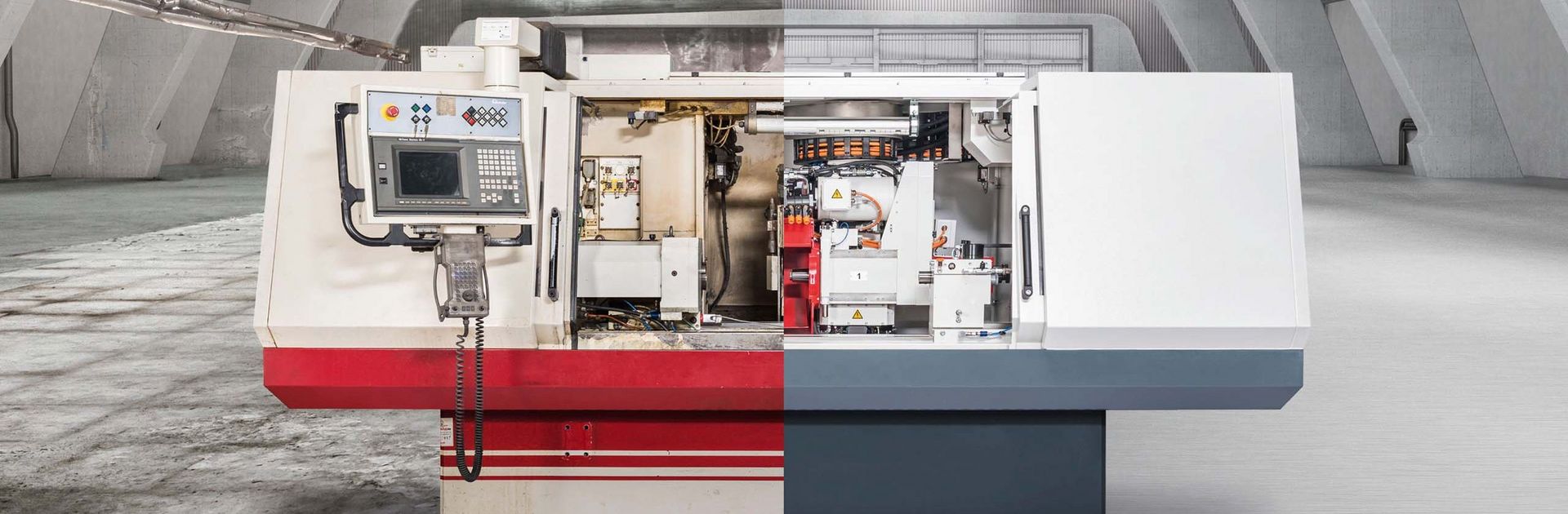

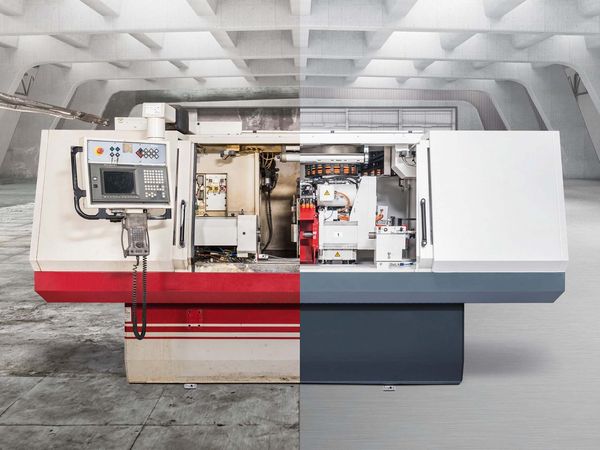

Keep on grinding: Machine rebuilding safeguards your production.

In a highly productive manufacturing facility, machine downtimes can quickly have negative effects on an order's profitability, cause longer lead times and ultimately jeopardize competitiveness. Replacing an older machine can also mean investments that challenge profitability to an even greater extent. To counteract this, an increasing number of companies rely on UNITED GRINDING's rebuild service.

The Customer Care departments at all UNITED GRINDING Group companies have been carrying out machine reconditioning for many years, turning old machines into new. In other words: a machine that is as good as new with tolerances the same as the original condition!

If machine demands have also changed, these can be configured and retrofitted during the reconditioning process according to customer demands. With materials, workshops and engineers under one roof the Reconditioning departments apply their expertise to double grinding machines' life cycles.

The guideways are completely overhauled or renewed, the assemblies are upgraded, the wear parts in the control cabinet are replaced, as are hydraulics and lubrication system parts as well as all valves. If old spare parts are no longer available, UNITED GRINDING will seek an alternative solution. Sheet metal panels and components are sand blasted and then repainted. After the rebuild, the geometry corresponds to that of a new machine.

In addition, the rebuild process can also include retrofitting new technologies into older systems. From simple upgrades to complex, specialized modifications, these new features allow you to react directly and quickly to demanding manufacturing requirements – or to meet the increasing demands of your customers.