Small Aerospace Parts Require Multitasking Grinding Machines

Massive turbine blades, expansive fuselage panels, and robust landing gear components. Many workshops focus on the production of large components for the aerospace industry. But the real challenge lies with the manufacturers of small parts. Precision screws and sophisticated brackets, the production of small blades, vanes, and fairings for the modern jet engines: All these delicate and small aerospace parts require grinding machines with exceptional performance. For this purpose, UNITED GRINDING has developed the MÄGERLE MFP 30 – a compact 5-axis grinding solution that maximizes space utilization and enables a smooth production flow.

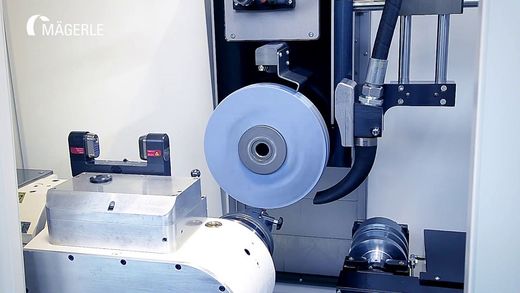

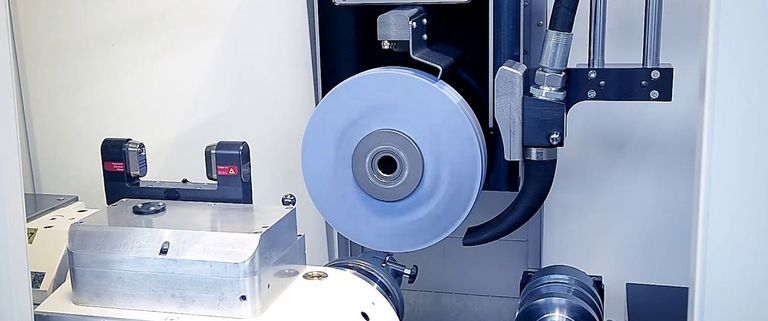

The MFP 30 ensures maximum effectiveness. For example, pre-loaded ball screws prevent backlash, while hydrostatic wrap-around guides in the Y-axis provide a dampening effect. This ensures accuracy and high metal removal rates with extended tool life. Dual bearings, servo motor drive, and the space-saving bi-directional table dresser allow reliable dressing over the entire speed range. Rigid HSK-B80 flange holders on the MFP 30 accommodates grinding wheels measuring 300 mm x 60 mm x 76.2 mm (11.8” x 2.36” x 3”), allowing for wide profiles.

For creep-feed grinding as well as conventional grinding, the MFP 30 scores with its direct drive 12,000 rpm spindle with a power of 26 kW (from 1,750 rpm) and high torque at low spindle speeds. The high speeds are suitable for grinding, milling, and drilling with plated CBN tools.

Multi-Process Capability

For the MFP 30 to have this multi-process capability, the machine has through-spindle cooling for chip removal, longer overall tool life, better part surface finish, and higher throughput. An automatic tool changer with 12 or 24 tool positions accommodates grinding wheels up to 12" as well as milling cutters and drills. At the customer's request, a measuring probe can also be installed to check the workpiece positioning and dimensions. A major production advantage of the MFP 30 is that operators can load and unload the tool changer while the machine is running. The multitasking capabilities enable parts to be machined in one setup and in multiple operations for maximum process reliability and cycle time reduction

For Complex Parts in One Clamping

The typical turbine blade is an example of how complex parts can be machined in one clamping. Machining such a part typically involves six operations. First, the machine grinds two profiles on one side of the blade with a standard corundum wheel. It then rotates the part in the B axis to grind two profiles on the other side.

After a tool change, the root surface is ground at the front and rear edge of the blade. Operation five is grinding a notch with a CBN wheel and number six is milling a pocket with a torus end mill. Performing these multiple operations in a single setup reduces cycle time, increases workpiece accuracy, and eliminates human error, for example, when transferring a workpiece between machines or stations.

When do smaller, more compact machines like the MFP 30 offer advantages – especially for certain components and operations in the aerospace industry? Obviously then, when shorter machining times, fewer set-up processes, and more efficient utilization of the workshop are the goal. Also then, when you have to react quickly to frequent changes in the production volume of small parts.