Lyon, here we come

At prestigious professional championships, STUDER apprentices regularly take top positions and thus show that its vocational training is among the best in the world. Motion was present at the training for WorldSkills 2024.

LIKE BEING IN THE MIDDLE OF A SWARM OF BEES was how Luis Salzmann said he felt. “There was an incredible noise in the hall, from the machines and the large audience,” recalls the 19-year-old of the day he won the gold medal.

He had to concentrate hard on his task to get the maximum number of points under competitive conditions. “My secret weapon was noise-canceling headphones,” the young man says, laughing. That was last fall during the IndustrySkills|SwissSkills Championship 2023 at the BERNEXPO site, where the Swiss technology and machinery industry selected its best young professionals.

And Salzmann, who is in his fourth year of apprenticeship at STUDER, made it to the top of the podium in the Industrial Design/EFZ discipline. This automatically qualified him for WorldSkills 2024, which will take place from September 10 - 15 in Lyon, France. According to the organizers, around 1,500 young professionals from over 65 countries will be competing there on the Euroexpo site. The expected audience is estimated at a quarter of a million people. The more than 50 competition disciplines range from Aircraft Maintenance to Mobile Robotics and Web Technology – and the best in each case will receive a medal in front of thousands of applauding spectators at the final ceremony in France’s third-largest football stadium (Groupama Stadium).

WITH CAD SOFTWARE AND PENCIL

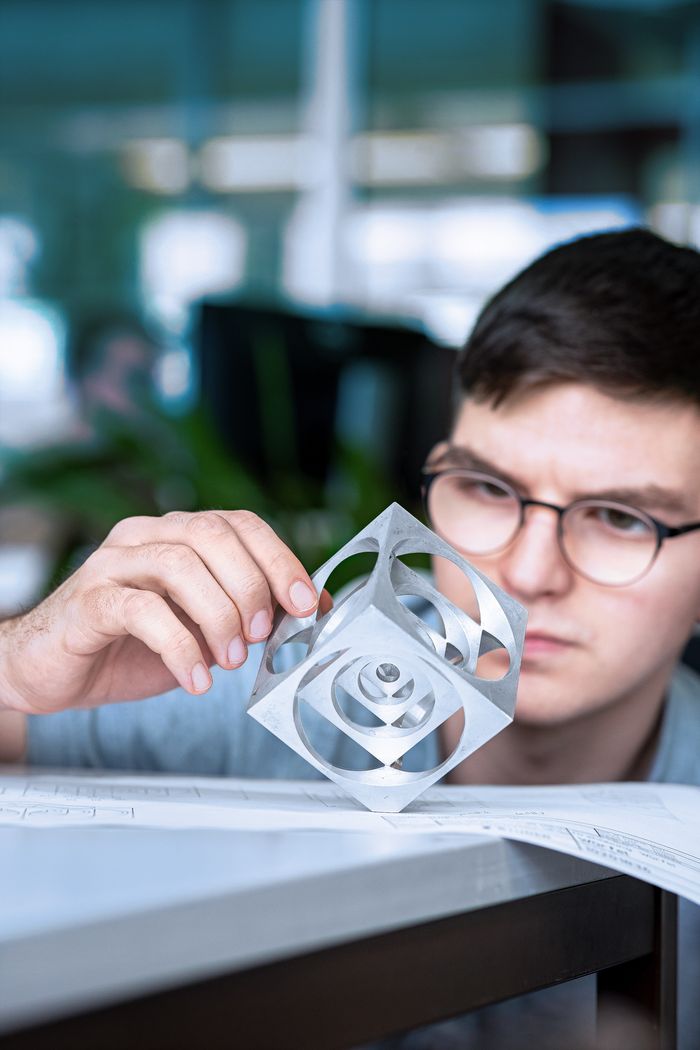

But Salzmann doesn’t want to think about that yet. He’s in the middle of the training phase and needs to maintain a clear head. He’s now sitting concentrated in front of a computer screen in the STUDER training workshop in Thun, Switzerland. The training machinery here is among the most modern in the country. In addition to conventional machines for basic training, there are also specialized devices for focused training and production. Salzmann is training for the profession of “Industrial Designer EFZ” and thus will be taking part in the discipline Mechanical Engineering CAD at WorldSkills. His most important tool is a computer with modern 3D CAD software.

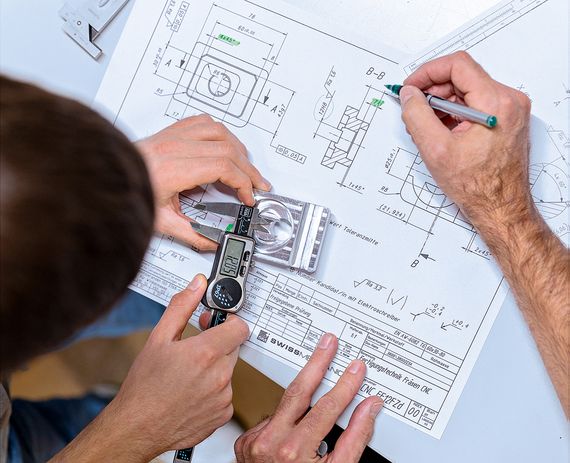

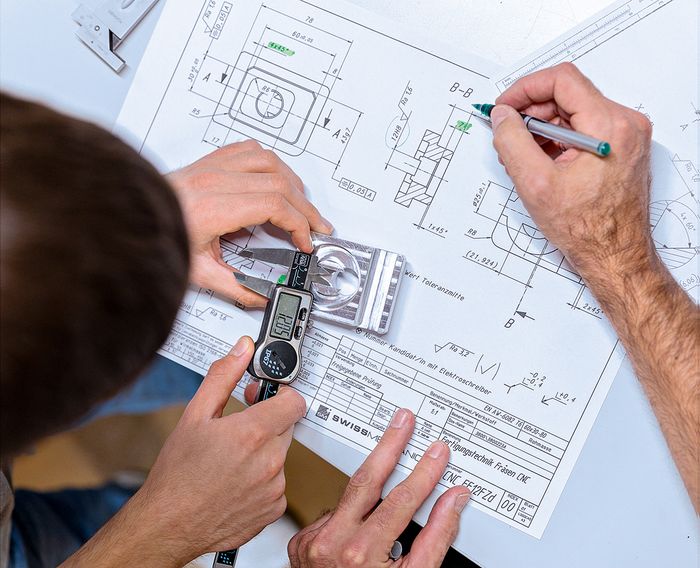

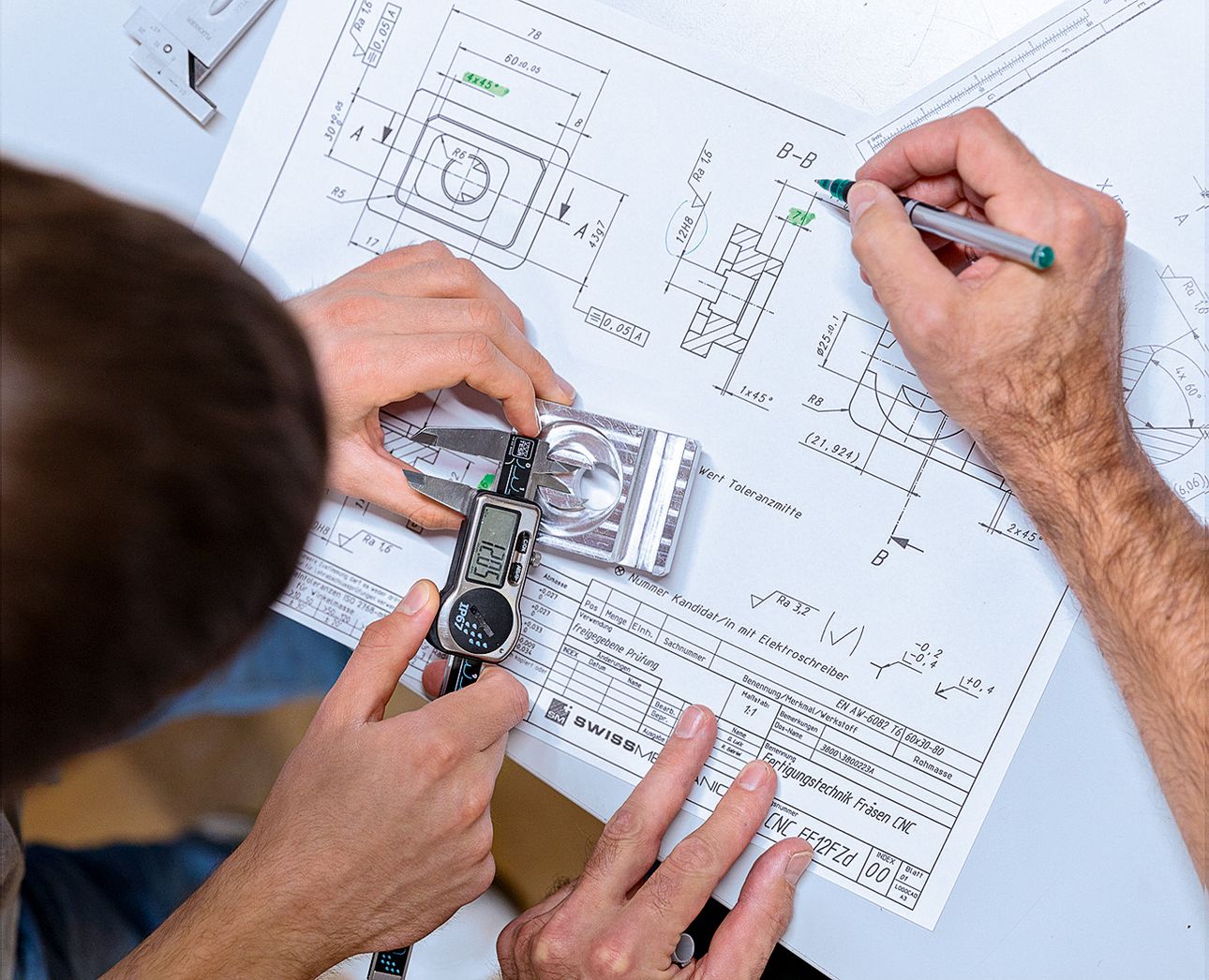

“But in our training, we also value working accurately with paper, pencil, ruler, compass, and vernier caliper gauges,” says Roger Leuenberger, Head of Vocational Training at STUDER. The company specializes in the manufacture of high-precision, high-tech cylindrical grinding machines and has with around ten percent, a high proportion of apprentices among its employees. “Because we train the majority of the staff we need ourselves, we are also well positioned in times of a shortage of skilled workers,” explains Leuenberger. The design specialists at STUDER, for example, design parts for the company’s production, parts which are later manufactured on cylindrical grinding machines by employees who are trained polymechanics.

Creating technical drawings or their precise dimensioning, transferring them to 3D CAD software, and recognizing technical interrelationships and functionalities: These are all typical tasks in this profession, both on a day-to-day basis and also at the championship. “But the big difference is that at WorldSkills, it’s all about time,” says Salzmann. As a rule, there is a specified number of hours during which the participants must complete a specific task. Whoever works more accurately, finishes faster, or accomplishes more than the competitor also receives more points.

INTENSIVE TRAINING

During training in the apprenticeship workshop, Salzmann repeatedly looks away from his computer screen and concentrates on a technical drawing on his desk. For non-professionals, the labyrinth of black and white lines, circles, angles, and units of measurement may be difficult to comprehend, but Salzmann quickly detects in it a pressure equalization cap for hydraulic systems. He now has to recreate this with high precision in 3D in the CAD software. Once this task has been solved, the next component follows. Be it a go-cart chassis, a valve spindle, or a swivel castor.

During training, he has two coaches who assist him: Mario Wymann is a professional vocational trainer at STUDER for the field of design and evaluates and advises Salzmann primarily on technical drawings. A trainer from the SwissSkills national team with the necessary knowledge of the international evaluation system is responsible for working with the CAD software. “So far, we have worked with the NX CAD software from Siemens for SwissSkills. But with Inventor from Autodesk, a different program is required for WorldSkills,” says Salzmann. This adjustment already demands a lot of familiarization and training time from him.

The closer WorldSkills gets, the more time Salzmann has to spend on preparing to fight through decades of archives of competition tasks day after day. Whereas at the beginning there were only one and a half work days per week, the training has gradually become a real full-time job. The personnel costs associated with this are also a major investment for STUDER. Why is the company doing it? “We have great training, and it naturally brings a great deal of renown when our apprentices win medals,” says Coach Wymann. Such success also opens up many career doors for the young people themselves.

LOTS OF MEDALS FOR STUDER

It is a fact that STUDER is regularly represented in the top positions. When Salzmann took first place at SwissSkills last year, his colleague Noah Rossel won the silver medal in the “Automation specialist EFZ” category. And then there’s polymechanic Gil Beutler, who won a whole set of precious metals for STUDER in the Swiss, Euro, and WorldSkills with gold, silver, and bronze from 2020 on. “Our medalists are ambassadors for the training as a whole,” explains training manager Leuenberger. The reason is simple, such successes make STUDER a particularly attractive training facility for young professionals who want to acquire their know-how from the best in the world. STUDER also continuously invests in state-of-the-art training machines for the training center. “As just recently with two new CNC machines,” adds Leuenberger.

Finally, there’s just one more question left: How does Salzmann rate his chances for Lyon? “It certainly won’t be easy. Switzerland hasn’t won any medals in my discipline for a long time, and the results from the past show that only a few points will make the difference,” he says. A slightly better CAD animation, a more precise detail shown, or a more accurate dimensioning: These things ultimately determine a place on the podium. Nevertheless, he’s confident. “In comparison to other countries, vocational training at STUDER and in Switzerland as a whole places a great deal of importance on a broader understanding of technical relationships from different fields – this is certainly an advantage,” he says, adding: “But being part of the Swiss national team alone is a great honor, and I'm already looking forward to the opening ceremony in Lyon.”