33 years PA-K head dressing device from JUNG

Over many years, surface grinding machines became profile grinding machines thanks to a Diaform dressing device.

For this purpose, templates were milled on a scale of 10:1 or 20:1 and clamped on the template table. Using a stylus moved along the template, the machine operator then copied the contour onto the grinding wheel. In this purely manual process, changes to the contour were only possible with great effort, usually only by making a new template.

With the introduction of CNC technology JUNG developed a head dressing device.

In 1987 the first profile grinding machine from JUNG with CNC head dresser PA30K was delivered. At that time the PA30K was still equipped with a single profile diamond and the contours were created in a complex process on a desktop computer from Hewlett Packard (HP) and stored on magnetic tape cassettes - a 16-bit processor and a main memory of 8 to 32 KB were the performance data of the HP 9825 at that time.

Today, 33 years later, JUNG is already delivering the fourth generation of the head dresser together with the J600.

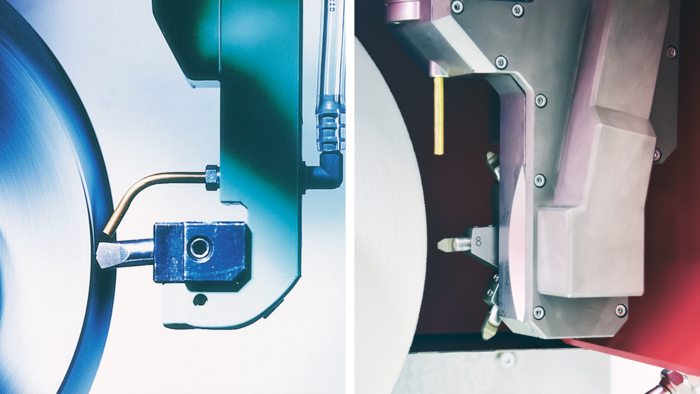

The PA-K37XT is considered a technology benchmark and can be used with diamond chisels or powered dressing wheels. Automatic adjustment of the dressing tools is a standard feature.