https://www.grinding.ch/en/

UNITED GRINDING

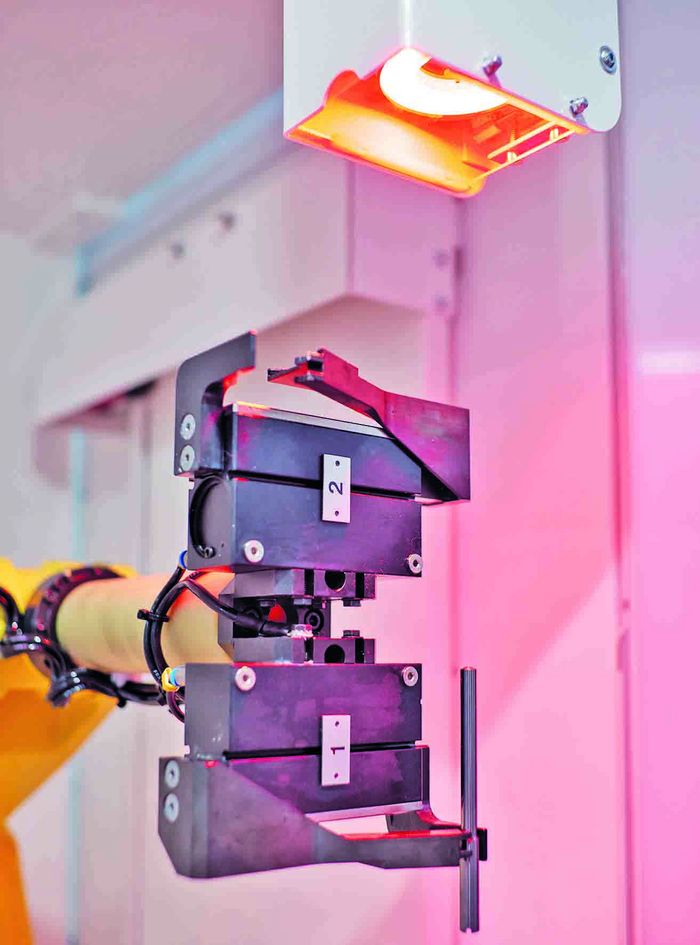

Automatic detection and alignment of tools and blanks

This system detects contact free, the orientation of the tool or blank, with e.g. brazed PCD plates on the front, sintered PCD veins or with cooling channels. The detecting is done automatically and during idle time. This means significant timesaving compared to the manual measurement method, eliminates human errors and avoids damage to the tool due to the non-contact method.

The TOOL VISION SYSTEM is permanently installed in the robot cell and available with two lenses. The one lens for tool diameter from 1.7 mm to 12 mm, the other lens for tool diameter from 6 mm to 32 mm.