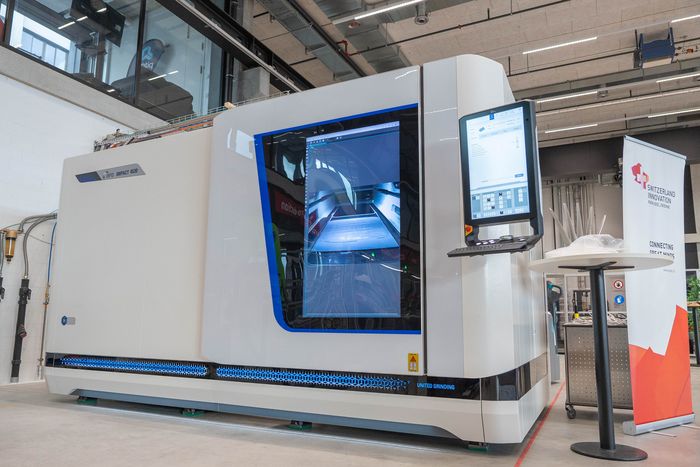

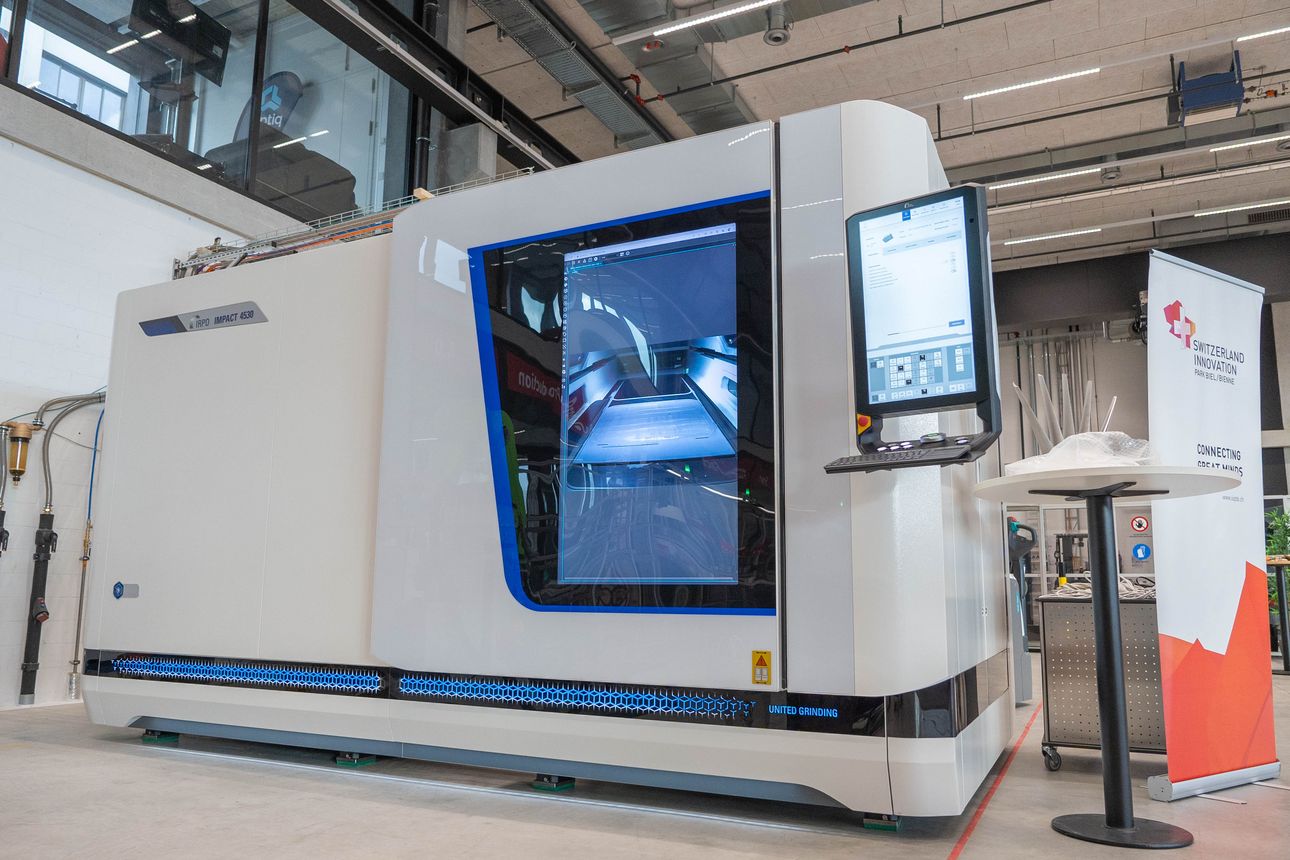

First additive machine tool IMPACT 4530 from IRPD reaches the market

The handover of the IMPACT 4530 took place on December 6, 2024 at SIPBB in Biel. The event was attended by representatives from IRPD, SIPBB and the UNITED GRINDING Group, who acknowledged the importance of the investment in speeches. "For SIPBB, whose mission is to promote the Swiss economy and create and maintain jobs in Switzerland, additive manufacturing is one of the focus areas," emphasized Felix Kunz, Chairman of the Board of Directors of SIPBB. The Innovation Park is a private non-profit organization that primarily supports and conducts applied, industry-related research and development. As part of the national and international network of the "Switzerland Innovation" foundation, the SIPBB generates research investments from abroad, promotes Swiss innovation performance, supports start-ups and accelerates the translation of research results into marketable products. By establishing topic-specific ecosystems in the focus areas of Smart Factory, Battery Technology, Health Tech and Advanced Manufacturing, the SIPBB has created a platform for exchange between companies and initiated collaboration between research and industry partners. The acquisition of the IMPACT 4530 is now intended to send a strong signal for Switzerland as a workplace.

Closing the gap

In his speech, Christoph Plüss, member of the Board of Directors at IRPD and CTO of the UNITED GRINDING Group, explained the Group's motivation for entering the additive manufacturing market. "Market analyses had shown that we could fill a gap with the development and construction of the first Swiss additive machine tool. This was a clear opportunity and motivation enough for the Group." IRPD then took on this task within the Group. "After six years of development, today is an important day for IRPD and the history of additive manufacturing in Switzerland - this fills me with pride," emphasizes Andreas Burn, Managing Director of SIPBB and Head of the Swiss Advanced Manufacturing Center, on the occasion of the handover of the IMPACT 4530. IRPD is a machine manufacturer in the field of additive manufacturing based in St. Gallen. In addition to its core business - the construction and sale of machines for additive manufacturing - IRPD is also active in the service sector. This includes consulting, seminars and workshops as well as contract manufacturing of high-quality components made of metal or plastic.

Alternative to conventional manufacturing processes

With the IMPACT 4530, SIPBB benefits from reliably high component quality, automation capability, short changeover times, low maintenance requirements and simple operation. The system works according to the LPBF process (Laser Powder Bed Fusion) and is equipped with a thermostabilized machine core and a vacuum-capable process chamber, which is a robust cast component with high rigidity and hermetic sealing. The system has a footprint of 450 mm x 300 mm and a height of 400 mm. While metal powder can be melted in micrometrethick layers using either two or four synchronized fibre lasers of 1,000 W each, sensor technology and cameras track the process in real time. The 54'' display on the machine al-lows the operator a clear view of the interior with all relevant data. The IMPACT 4530 is equipped with "C.O.R.E.", the hardware and software architecture for machine tools from the UNITED GRINDING Group. The user-friendly 24'' operating panel with icon-based interface allows intuitive, efficient operation even without programming knowledge. In addition, the IMPACT 4530 has a high level of system autonomy and can be scaled as a stand-alone machine or a fully automated system network. The Laser Powder Bed Fusion (LPBF) process is ideal for the automated production of components - particularly those with highly complex geometries in single-part production, where it represents an efficient, economical alternative to conventional manufacturing processes. It opens up new potential for the automotive industry as well as the aerospace and medical technology sectors.

Cooperation with great potential

"This is based on the keywords Switzerland, research, proximity to industry and applications as well as employee qualifications." Lang ceremoniously handed over the key to the IMPACT 4530 with obvious pleasure at the forthcoming collaboration.