Use of additive processes to manufacture innovative extrusion dies to extend the process limits in the production of complex aluminum profiles

Motivation

In aluminum extrusion, the temperature development in the material flow and in the dies has a strong influence on the resulting product quality and process performance. The temperature increase caused by friction and deformation work is therefore a limiting factor for productivity increase.

Within the framework of a state-funded research project, the companies WEFASwiss AG (manufacturer of extrusion tools), Aluminium Laufen AG ( consumer of extrusion tools for the production of aluminium profiles) and Irpd AG (service provider for additive manufacturing processes), under the guidance of the research partner Inspire of ETH Zurich, implemented the idea of mapping an added value, by means of additive manufacturing via near-contour cooling channels on the mandrel insert of an extrusion tool. The aim was to generate productivity advantages in extrusion by increasing the press speed.

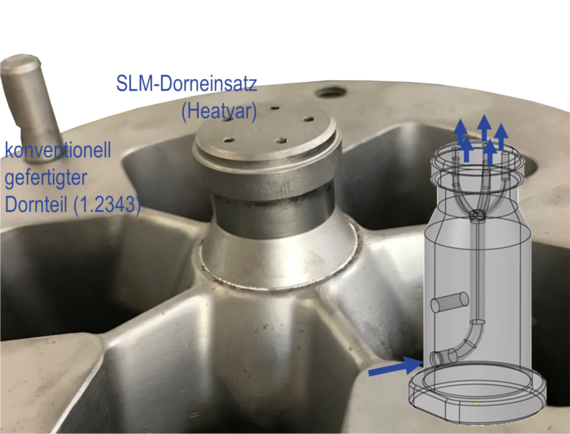

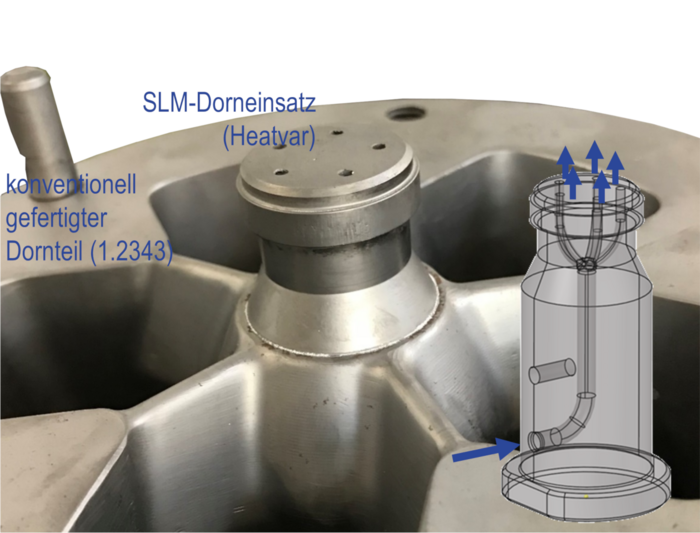

Implementation in hybrid construction

The use of Selective Laser Melting (SLM) in the field of extrusion dies poses several challenges with regard to the manufacturing process and material properties. To overcome manufacturing and material limitations, extrusion dies were manufactured using a hybrid manufacturing approach. Behind this approach is the idea of continuing to manufacture the majority of components in the conventional way where no significant potential for a desired service life or throughput optimization can be realized. However, where an added value can be sensibly realized - in this case in the form of near-contour cooling channels in the mandrel insert - the additive manufacturing process SLM was used to implement the complex cooling channel geometry. Against the background of the required temperature resistance, the tool steel Heatvar, which was specially developed for use at high temperatures, was qualified for the SLM process, processed and finally successfully tested on the press.

Thanks to the high degree of geometrical freedom, which is an essential unique selling point of additive manufacturing technologies, it was possible to integrate a conformal cooling channel for nitrogen-based temperature control of the tool in temperature-critical areas of the mandrel insert. From a thermal-mechanical point of view, a channel with outlet in the pressing direction proved to be promising and was therefore tested in this form on several tools.

Results

Extrusion experiments with and without liquid nitrogen cooling were performed for three profile geometries. For the first two cylindrical hollow profiles, the degree of complexity was defined by adjusting the wall thickness. In these cases, the punching speed, which correlates directly with the increase in productivity, could be increased by 24% and 33% respectively. In the third application, in addition to the mandrel part, the die was cooled, also in order to optimize the temperature inhomogeneity across the profile cross section. In this case, an increase in punch speed of 40% has been achieved.

The process chain developed and validated in an industrial setting shows that the integration of cooling channels manufactured with AM technology in the hybrid extrusion die helps to increase productivity.